Introduction

In recent years, Southeast Asia has witnessed a remarkable transformation in its electronics manufacturing and supply chain landscape. Among the frontrunners in this region are Thailand and Malaysia, which have rapidly emerged as key players in the global electronics industry.

The convergence of several strategic factors has propelled these nations to the forefront of electronics manufacturing, attracting both established companies and startups alike. In this blog, we will delve into the reasons behind Thailand and Malaysia’s ascent to becoming pivotal locations for electronics manufacturing and the supply chain.

Strategic Geographical Location

Situated at the crossroads of major shipping routes, both Thailand and Malaysia enjoy a strategic geographical advantage. Their proximity to key consumer markets, such as China, India, and ASEAN member countries, provides them with easy access to both input materials and end markets. This geographical centrality reduces transportation costs and lead times, making them attractive choices for electronics companies looking to optimize their supply chains.

Robust Infrastructure

Investments in infrastructure have played a pivotal role in propelling Thailand and Malaysia to their current status. These nations have heavily invested in ports, roads, airports, and industrial zones to create an efficient and well-connected ecosystem. Thailand’s Eastern Economic Corridor (EEC) and Malaysia’s Multimedia Super Corridor (MSC) are prime examples of such initiatives that foster innovation, manufacturing, and technology growth.

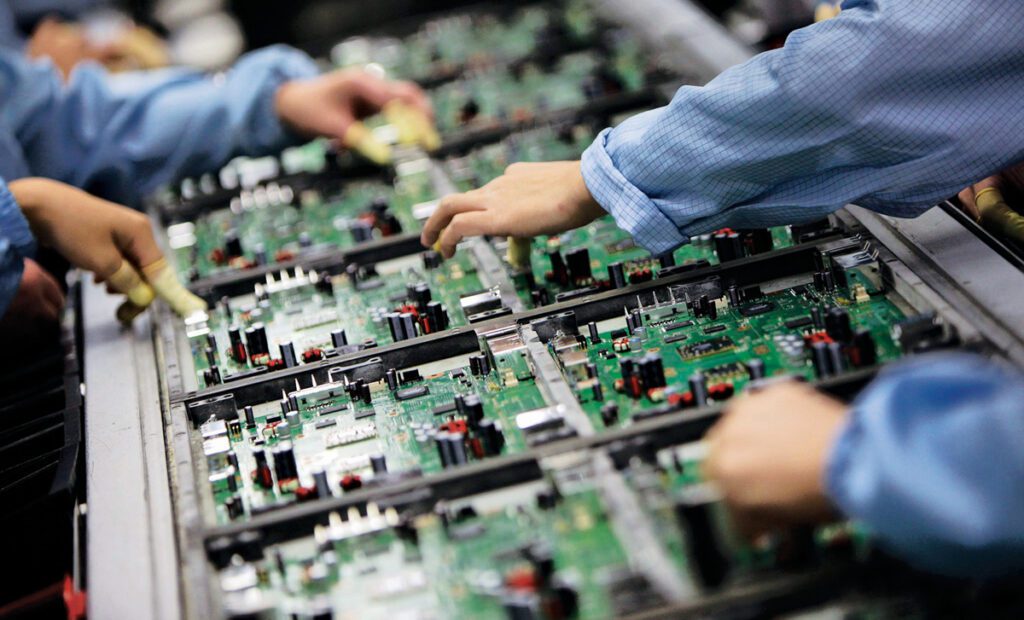

Skilled Workforce

Both countries have invested in education and training to develop a skilled workforce capable of meeting the demands of the electronics industry. Local universities collaborate with industry players to offer specialized programs in engineering, technology, and related fields. This has led to a pool of talented professionals and engineers who are crucial to the design, production, and management of electronics manufacturing processes.

Government Support and Incentives

Thailand and Malaysia have implemented attractive incentive programs and policies to lure electronics manufacturers. These incentives include tax breaks, grants, research and development (R&D) incentives, and streamlined administrative processes. The governments also offer various schemes to encourage innovation and collaboration between academia and industry, fostering an environment conducive to technological advancement.

Strong Ecosystem and Supply Chain Network

Both countries have established robust ecosystems that encompass everything from raw materials and component suppliers to manufacturing facilities and distribution networks. This comprehensive supply chain network reduces production bottlenecks, minimizes risks, and ensures a smooth flow of materials and products.

Diversification and Innovation

Thailand and Malaysia have successfully diversified their economies, moving beyond traditional industries. They now focus on producing high-value products and components, including semiconductors, consumer electronics, medical devices, and automotive electronics. This focus on innovation has helped attract multinational corporations seeking cutting-edge technology and manufacturing capabilities.

Pro-Business Policies

Thailand and Malaysia have demonstrated a commitment to creating business-friendly environments. Ease of doing business, protection of intellectual property rights, and transparent regulations are key factors that contribute to their attractiveness for electronics manufacturing. For example:

Board of Investment (BOI) Promotion: Thailand’s Board of Investment offers various incentives and promotions to attract foreign investment in key industries, such as manufacturing, technology, and services. These incentives include tax holidays, reduced import duties, and the ability to own land.

Infrastructure Development: The Thai government has invested in infrastructure development projects, including transportation networks, ports, and industrial zones, to improve connectivity and support business activities.

Ease of Doing Business Reforms: Thailand has made efforts to improve its business environment by streamlining bureaucratic processes and reducing red tape. These reforms aim to make it easier for businesses to start and operate in the country.

Multimedia Super Corridor (MSC): Malaysia established the MSC as a technology hub to attract technology and knowledge-based companies. Companies located in the MSC are eligible for tax exemptions and other benefits.

Digital Economy Initiatives: Malaysia has launched initiatives to promote its digital economy, including incentives for tech startups and investment in digital infrastructure.

Infrastructure Development: The Malaysian government has invested in infrastructure projects like the Mass Rapid Transit (MRT) system and the development of industrial zones to enhance connectivity and facilitate business operations.

Stability and Political Climate

The political stability in both countries provides a conducive environment for businesses to thrive. A stable political climate helps maintain investor confidence and encourages long-term commitments from multinational corporations.

Conclusion

The rapid rise of Thailand and Malaysia as prominent locations for electronics manufacturing and supply chain activities is a result of a combination of factors. Their strategic geographical location, strong infrastructure, skilled workforce, government support, well-established ecosystems, and pro-business policies have all contributed to their ascent in the global electronics industry. As these nations continue to invest in innovation and technology, they are likely to remain integral to the global electronics manufacturing and supply chain landscape for years to come.